Econosto includes numerous internationally operating wholesale companies and, as a market-oriented knowledge organization, supplies high quality hoses, gaskets, seals, packing, suitable for each application.

-

Seals form an essential part of the pipework and equipment in modern chemical and petrochemical installations (e.g. heat exchangers). Installation reliability depends for great part on the correct functioning of seals.

The primary demands on a seal are the following:

- Temperature resistance

- Compressive strength

- Resistance to the medium to be sealed

Besides choosing the correct type of seal and/or the correct sealing material, it is of great importance that the flange parts between which the gasket must be fitted are suitable for the chosen seal with regards to flange roughness and it must be possible to generate sufficient gasket pressure to realize the seal realize.

Another, very important factor is the installation of the gasket. it is important that the gasket is installed with the correct gasket stress being applied.

An accurate calculation of the flange joint can be made for heat exchangers as well as for flange joints.

-

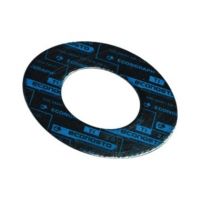

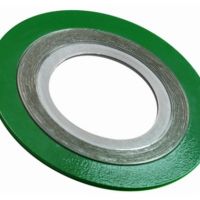

These seals are used to seal two elements that are permanently stationary in relation to each other. Examples of this are pipe sections joined by means of flanges and gasket to guarantee the leakproof transport of e.g. liquids or gases. Parts of equipment such as e.g. heat exchangers are also provided with static seals to prevent leakage and to make the efficiency of the appliance as high as possible. Static seals can be sub-divided into:

- Metallic and semi-metallic gaskets (camprofile gaskets, spiral wound gaskets, ring joint gaskets, lens (shaped) rings, welded membranes, superseals)

- Sheet gaskets (Aramid fibre, graphite, PTFE)

-

This is the sealing of two elements that are in motion in relation to each other. This can be rotating as well as oscillating movements. Examples of this are e.g. the stems of valves and piston-rods in pneumatic cylinders. Higher (peripheral) speeds occur on the output shafts of e.g. pumps or compressors. These applications require very special seals, which are referred to as mechanical seals.

In this catalogue we restrict ourselves to the product groups gland packings and O-rings.

-

A rubber hose is the most used kind of industrial hose. The success is mainly thanks to many available qualities of rubber. Because of the large variety of synthetic rubber qualities, there is a suitable solution for almost every application.

Rubber hoses consist of a lining, inserts and a cover. The inner wall of the hose must be resistant to the liquid or the gas that is transported through the hose. One should pay attention to mechanical (resistance to wear) thermal and chemical characteristics and the required impermeability to gas.

The inserts ensure pressure resistance and shape stability of the hose. The outer wall must be sufficiently resistant to outside influences such as wear, mechanical loading, influence of the weather, temperature, chemicals, oils, etc.

ECONOSTO has to offer a wide range of hoses for every application and need

- Compressed air hoses

- Water hoses

- Gas hoses (propane, oxygen, acetylene)

- Steam hoses

- Petrol and oil resistant hoses

- Tank truck hoses

- Bunker hoses

- Food hoses

- Chemical hoses

- Wear resistant hoses

- Hydraulic hoses

- Plastic hoses

- PTFE hoses

- Composite hoses

-

Composite hoses are exceptionally light and flexible hoses, incorporating a metal inner spiral and various plastic windings. The Deltaflex-® composite hoses produced by Econosto are lighter and easier to use than rubber hoses and feature minimum dilation and a universally chemical resistant. They are used primarily for filling and emptying the liquid tanks of ships, tankers and rail wagons.